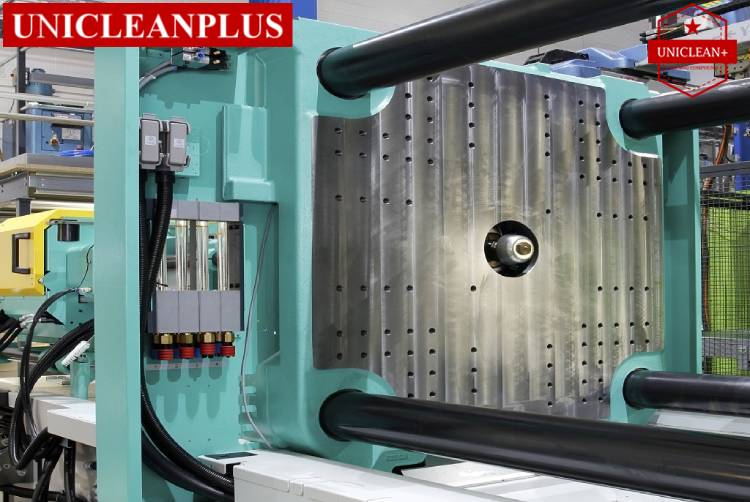

As a manufacturer in the plastic processing industry, you know that every minute of downtime can mean lost revenue and unhappy customers. One of the most common issues in plastic processing is equipment downtime caused by machine cleanouts and colour changes. These interruptions can be costly, time-consuming, and frustrating for everyone involved. However, with the help of a trusted Purging Compound Supplier, you can solve your plastic processing problems and keep your operations running smoothly.

What is a Purging Compound?

Purging compounds are a specialized material used to clean and maintain plastic processing equipment. Purging Compound for Plastic is designed to remove residual materials from machinery, such as colourants, carbon deposits, and contaminants, that can accumulate over time and impact machine performance.

How Can a Purging Compound Supplier Help?

A reliable supplier of purging items can help you in a variety of ways, including:

Providing Expert Advice: A trusted supplier will have the knowledge and expertise to help you select the right Purging Material for your specific needs. They can also provide guidance and free samples to understand the proper usage and application of the product.

Saving Time and Money: By using a Purging Compound regularly, you can reduce the need for extensive machine cleanouts and colour changes. This saves you time and money by minimizing downtime and increasing productivity.

Improving Quality: These compounds can improve the quality of your products by removing contaminants that can cause defects, such as black specs or discolouration.

Increasing Machine Life: Regular use of these cleaning compounds can help extend the life of your machinery by keeping it clean and preventing the build-up of materials that can cause damage.

Enhancing Safety: Clean equipment is safer equipment. By removing residual materials, you can reduce the risk of equipment malfunction or operator injury.

Choosing the Right Purging Compound Supplier

When selecting a reputed supplier of the Purging Compound, there are several factors to consider. Look for a supplier with a strong reputation for quality and reliability and be sure to ask for references or case studies from other clients in your industry. Additionally, consider the supplier’s level of technical support and availability of training resources. A good supplier should be able to offer guidance and support throughout the purchasing process and beyond.

A trusted supplier can help you solve your plastic processing problems and keep your operations running smoothly. By selecting the right supplier and using Purging Material regularly, you can improve productivity, quality, and safety while reducing downtime and costs. Do not let machine cleanouts and colour changes slow you down – partner with a reliable supplier today and take your plastic processing to the next level.

If you desire to have the best purging compounds it is wise to be with UNICLEANPLUS. Their uniqueness is not only in the quality of their products but also making it possible to have trial samples before you purchase purging materials. Using the free samples, you can know which compound is ideal for your situation and place a bulk order for that. You can connect them at +91 9021232809.

Comments

Post a Comment